Product List

- Welding Manipulator

- Welding Positioner

- Welding Rotator

- Adjustable Welding Rotator

- Conventional Welding Rotator

- Special Welding Rotator

- Welding Turntable

- CNC Cutting Machine

- Laser Cutting Machine

- CNC Flame Cutter

- CNC Plasma Cutter

- CNC Table Cutting Machine

- H Beam Production Line

- Wind Tower Production Line

- Robotic Welding Automation

Wind Tower Production Line (Wind Tower Welding Line)

Description of Wind Tower Production Line:

This wind tower welding line is specially designed for the submerged-arc welding of outer circular seam of wind power generator tower pole. It adopts cantilever structure, and can use several single cantilever structures to make up a welding workstation so that it can do multi-pass welding. In this way, its welding efficiency can be greatly increased.

This wind tower welding line is mainly composed of bending machine (rolling machine), CNC cutting machine, welding equipment, welding rotator set, and sandblasting and painting turning rolls.

We provide the on-stop service, Design-Produce-Assemble-After sales service:

1. Design and planning service for the whole production process.

2. Assembling and training for the whole production process.

3. A long after-sale service for the whole production process.

With strong professional R&D team and mature whole production process.

With controlling with every link of the whole production process.

With many successful cases for the tower tube production.

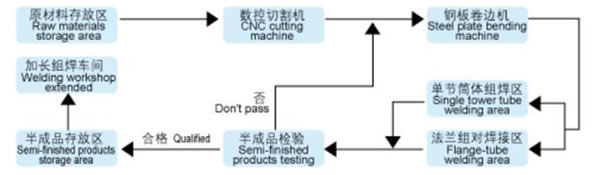

Single Tower Tube Production Process:

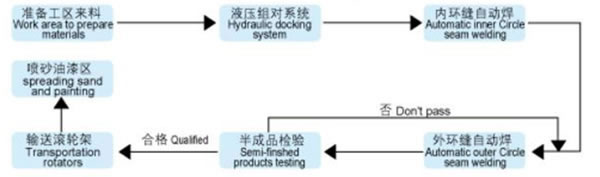

Multiple Tower Tubes Production Process:

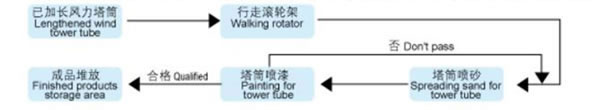

Tower Tube Sandblasting and Painting Production Process:

ABK Machinery is a professional wind tower production line manufacturer in China. You will be satisfied with our wind tower welding line, which is exported to Brazil, Germany, France, Italy, Vietnam, Singapore, Spain and other countries. We have always conducted our business in a sincere manner and with the purpose of achieving mutual benefit and win-win results with our customers.

Related Products

- Robotic Welding AutomationThe arc welding robots has a maximum 1.6m reach of arms, bigger than other brands’ robots of the same kind. Meanwhile, it can perfectly match welding sources of many brands. Equiping with dedicated arc welding software package, this robot can satisfy customers’ high-efficient and accurate requirement of welding technology. It can widely applies in auto parts, steel furniture, fitness equipment...

- Boiler Welding EquipmentThe boiler manipulator is used for flat welding, butt welding seam and internal and external longitudinal welding seam of cylindrical body and it can be fitted with roller stand for welding seam of internal and external circular welding seam. If it is fitted with positioner, different type of body can be made for different places of welding. Main body box type welding structure is treating by stress after welding and fine...